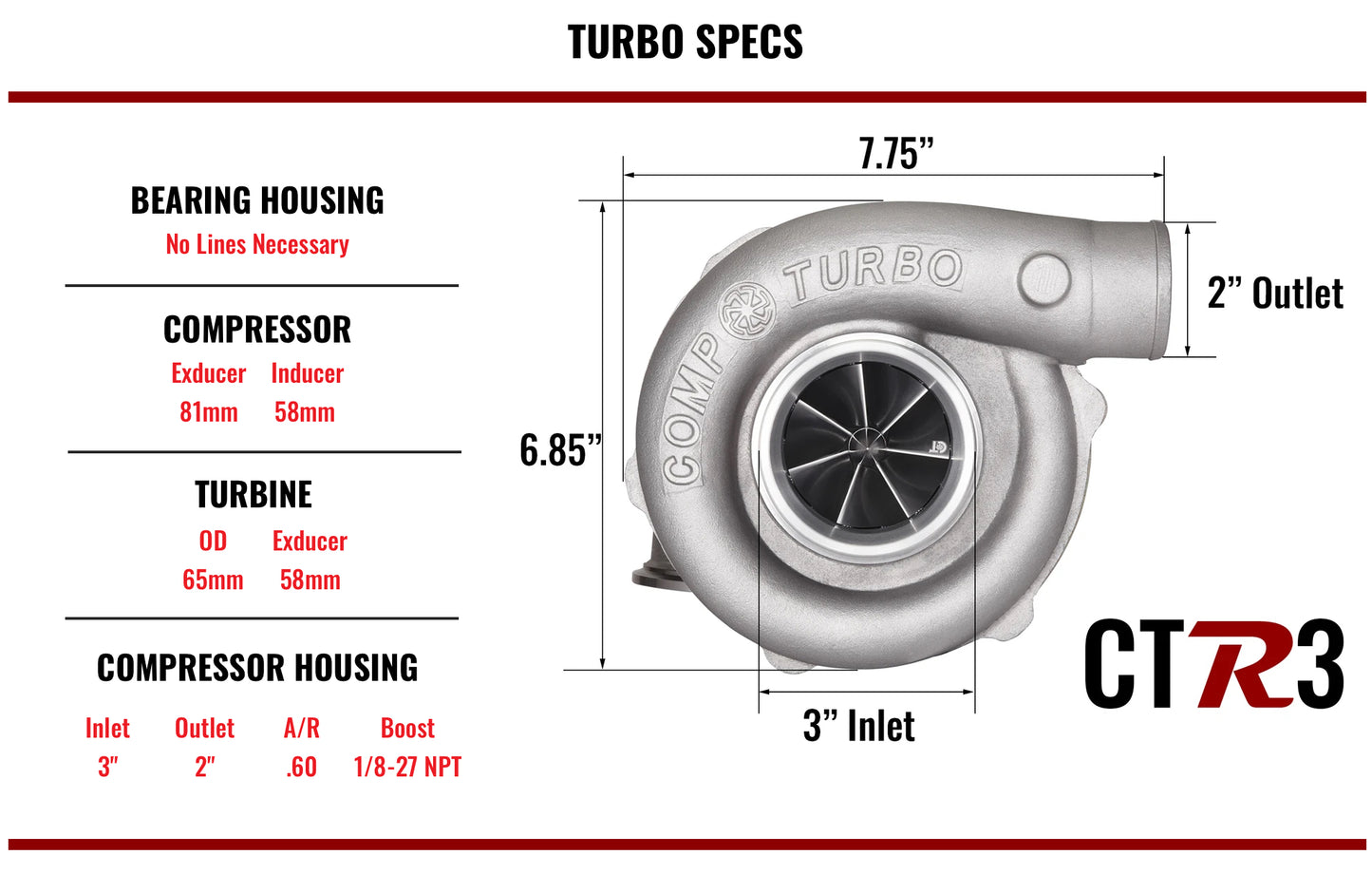

Comp Turbo Technology

Comp Turbo CTR-3018E-5858

Couldn't load pickup availability

Comp Turbo CTR-3018-5858

Select Exhaust Housing

Rated up to 650hp

1.4liter to 3.0liter engine capacity

FEATURES:

Lubrication is essential for turbochargers which rotate at extremely high speeds. The use of engine oil to lubricate turbocharger bearing systems has long been the standard, but not without its limitations and inconveniences. Oil lubricated systems offer limited mounting options where oil must be gravity fed back into the engine unless incorporating expensive and complicated scavenging systems.

Oil lubricated systems are also susceptible to contaminants from engine wear and are susceptible to leaking and smoking. These factors served as motivation to remove the use of engine oil from turbocharger bearing systems, thereby eliminating the problems associated. Comp Turbo's innovative design and technology led to the development and introduction of the world's first production oil-less turbocharger!

The patented CTR Oil-Less Turbochargers employ a version of the Triplex Ceramic triple ball bearing system where bearings are lubricated by a proprietary high-quality non-channeling grease. The bearing housing of the Air-Cooled model incorporates an internal air passage from behind the compressor wheel for cooling in place of a water jacket. Without the need for oil or water lines, and a Zerk fitting for easy servicing, the CTR Air-Cooled Triplex Ceramic Turbochargers are the ultimate choice for low, mid, or remote mount combinations.

Comp Turbo ball bearing turbochargers feature a patented triple ball bearing design boasting a 99% mechanical efficiency! Resulting in a faster transient response over the industry standard dual ball bearing system due to minimized friction losses. Dramatically improving response times and maximizing power output!

Our patented Triplex Ceramic bearing system is housed within a billet aluminum housing making our turbochargers an average of 5 to 12 pounds lighter than others! Our complete line of turbochargers is proudly made in the USA and feature our latest R-Line technology! Consisting of the CTR 7/14 veined billet slim hub extended tip compressor wheel and CTR slim hub lightweight turbine wheel, our most advanced rotor technology yet!