The fuel pump relay setup is one of the most widely used mechanism to wire high-flow fuel pumps. Not just for Nissan performance automotive applications but widely across the spectrum of motorsports, between virtually all manufactures, and across a wide variety of uses.

Relays are used in other high-current draw applications such as electronic water pumps, cooling fans, exterior lighting, HVAC control, engine starters, etc. The basis of relays is that a low current switch can control a high current applications.

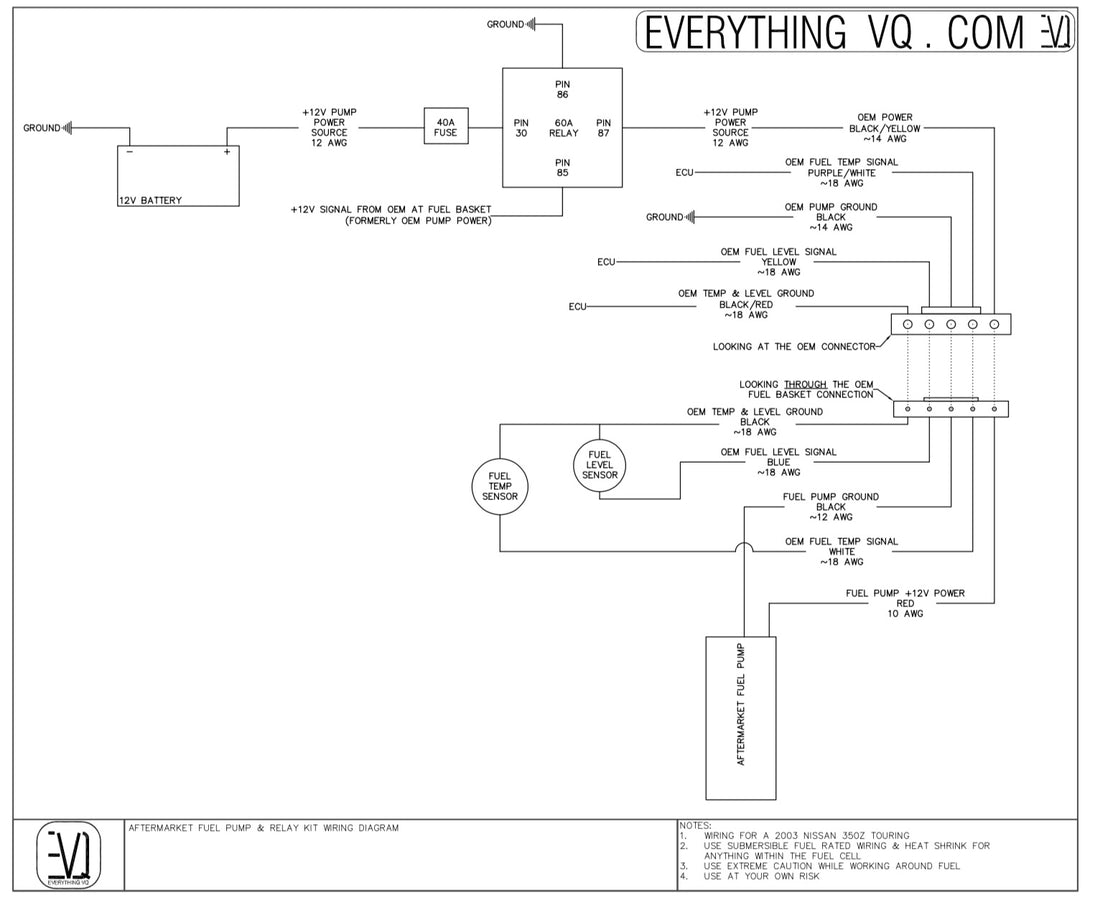

The purpose of this post is to show the wiring of a standard relay used to power an aftermarket fuel pump. This information is based on a early generation nissan 350z and your application may be different.

The best relay to use is a 4 post relay with a relay holder.

Post 87 - Connects to the positive wire of the fuel pump.

Post 86 - Ground (connect to a bare/unpained portion of the chassis with a secure nut & bolts, self tapping screws are not recommended)

Post 85 - Trigger (will connect to the OEM fuel pump positive wire)

Post 30 - Connects to the main power source (in our case the positive terminal of the battery)

A few notes:

Its best to use a 40a or higher rated relay in this application and purchase a relay kit that includes a relay holder.

Use an inline fuse between the battery and the relay.

Use extreme caution and you’re at your own risk while working with fuel. Its suggested you drain the fuel tank completely and have no open flames, heat sources, or ignition sources anywhere near the vehicle while this work is performed. You should also be in a well ventilated space. If you are not capable or are uncomfortable of handling these tasks than you should take your car to a shop that is familiar with this work.

It’s wise to upgrade your power wire to a 12awg or 14awg wire between the relay and the fuel pump. This can be over-done and too big of a wire can burn-out your OEM terminal pins.

Ensure your Pin 30 wire (that connects to the battery) is well insulated, sufficiently protected, and secure. You do not want this wire rubbing on any bare metal of the chassis. If the conductor becomes exposed to the chassis it could cause damage to the car.

It’s wise to use fuel grade / fuel rated wire and heat shrink anytime you’re re-wiring anything within the fuel cell or will be exposed to fuel.

Soldering wires is rarely the preferred method of connecting wires but is acceptale in the fuel basket if youre connecting the pump wires directly to the OEM pin leads embedded in the plastic.